Metal Castings: How Process Selection Impacts Performance and Efficiency

Light weight aluminum Castings 101: Comprehensive Information and High Quality Services for Your Jobs

Light weight aluminum spreadings provide a trusted alternative for different sectors, supplying a distinct mix of sturdiness and light-weight characteristics. Comprehending the various casting procedures is crucial for choosing the finest technique for specific projects. As modern technology developments, the landscape of light weight aluminum casting remains to alter, opening up brand-new possibilities. Discovering the nuances of these methods exposes vital understandings that can influence project results considerably. What factors should one think about when choosing a casting solution?

Recognizing Aluminum Spreading Processes

Aluminum casting processes offer as a structure for generating a large array of metal components used in various markets. These procedures entail the transformation of molten aluminum right into details forms with mold and mildews. Common methods consist of sand spreading, die casting, and investment casting, each offering unique advantages based on the application.

In sand casting, a mixture of sand and binder creates a mold, allowing for complex styles and better adaptability in manufacturing. Pass away casting makes use of high-pressure methods to infuse liquified light weight aluminum right into steel mold and mildews, leading to exact dimensions and smooth finishes. Financial investment casting, also referred to as lost-wax spreading, permits for very described parts, making it ideal for complex geometries.

Understanding these procedures is essential for designers and producers to pick the ideal method for their tasks. Each technique contributes distinctive characteristics to the last item, influencing its efficiency and suitability for details applications in numerous fields.

Advantages of Making Use Of Light Weight Aluminum Castings

The benefits of utilizing aluminum spreadings are substantial, making them a favored choice throughout various markets. Light weight aluminum spreadings supply excellent strength-to-weight proportions, making sure that parts remain lightweight without sacrificing longevity. This particular is especially beneficial in applications where minimizing weight is necessary, such as in aerospace and vehicle industries.

Furthermore, light weight aluminum's natural rust resistance boosts the long life of actors components, lowering the requirement for safety finishings and upkeep. The flexibility of aluminum enables complex designs and forms, enabling manufacturers to create complex components with precision.

Light weight aluminum spreadings show exceptional thermal and electric conductivity, making them perfect for heat-exchanging applications and electrical components. The recycling capabilities of aluminum likewise contribute to ecological sustainability, as it can be melted and reused with minimal power expense. In general, these benefits underscore light weight aluminum castings' increasing adoption in modern-day manufacturing processes, mirroring their efficiency and reliability.

Common Applications of Light Weight Aluminum Castings

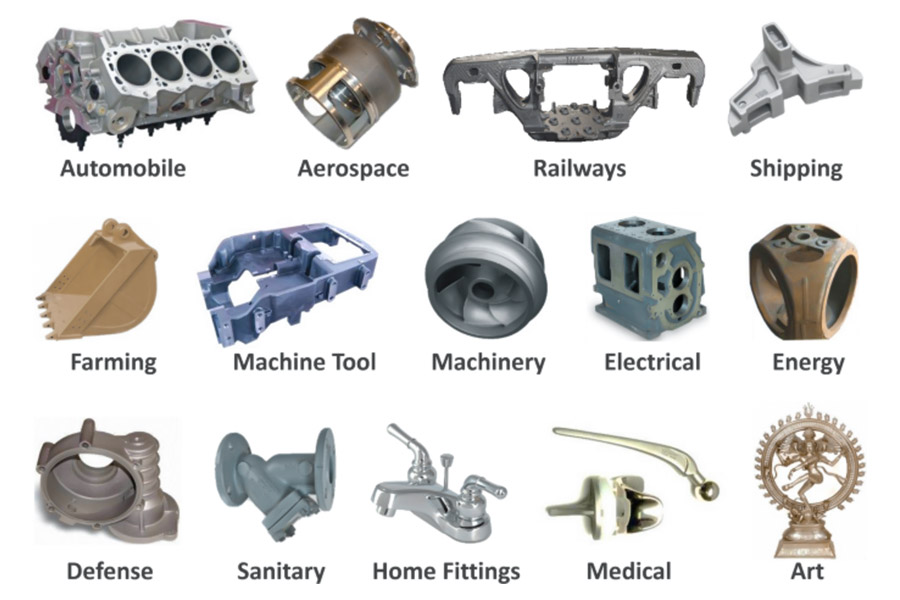

Commonly recognized for their convenience, light weight aluminum castings find application throughout various industries, including auto, aerospace, and electronics. In the automotive market, they are generally used for engine elements, transmission situations, and architectural components, providing light-weight options that improve gas effectiveness (Aluminum Castings). Aerospace applications gain from light weight aluminum castings partly such as braces, real estates, and architectural elements, where strength-to-weight ratio is vital

In electronic devices, light weight aluminum castings function as rooms and heat sinks, efficiently dissipating warm while offering security for delicate elements. The home appliance market utilizes light weight aluminum castings for numerous components and real estates, ensuring durability and visual charm. Additionally, the construction sector uses aluminum spreadings in attractive functions and building elements, blending performance with style. Overall, the diverse applications of light weight aluminum spreadings show their necessary function in modern manufacturing, driven by their special residential properties and versatility to fulfill industry-specific demands.

Kinds of Aluminum Casting Techniques

The various light weight aluminum spreading strategies each offer special advantages suited to different applications. Sand spreading is known for its flexibility and cost-effectiveness, while die spreading offers superb dimensional precision and surface area coating. Investment spreading, on the other hand, is celebrated for its capability to produce detailed geometries with high precision.

Sand Spreading Process

Sand casting stands out as one of one of the most popular methods for aluminum casting as a result of its flexibility and cost-effectiveness. This process involves creating a mold and mildew from sand, which is then full of liquified aluminum to create a wanted form. The sand blend normally includes silica sand, water, and clay, providing the needed stamina and flexibility for mold formation. When the liquified steel is poured into the mold, it strengthens and cools, after which the sand is removed, revealing the cast component. Sand spreading is particularly helpful for creating intricate geometries and big parts. Furthermore, it accommodates low production volumes effectively, making it appropriate for prototypes and custom components. In general, sand casting continues to be a fundamental strategy in the light weight aluminum casting sector.

Die Spreading Advantages

Die casting offers numerous advantages that make it a favored choice in the light weight aluminum casting industry. This approach enables the manufacturing of complicated forms with high dimensional precision, lowering the demand for substantial machining. In addition, pass away casting is characterized by its rapid manufacturing rate, enabling producers to meet large-volume demands effectively. The process also leads to a smooth surface area coating, which minimizes post-processing requirements. Additionally, die casting uses recyclable mold and mildews, resulting in lower per-unit costs in time. The integral stamina and have a peek here light-weight homes of aluminum enhance the durability of the last products, making them appropriate for various applications. In general, pass away casting presents a combination of efficiency, accuracy, and cost-effectiveness that interest numerous sectors.

Investment Casting Precision

Financial investment spreading is renowned for its precision and capacity to create detailed layouts with tight resistances, making it a very related to strategy in the aluminum spreading landscape. This approach includes creating a wax pattern, which is covered with a ceramic covering and consequently warmed to eliminate the wax, leaving a mold and mildew for liquified aluminum. The low thermal development of the materials guarantees dimensional precision and repeatability in manufacturing. Financial investment spreading is specifically advantageous for thin-walled elements and complicated shapes, which are challenging to achieve with other spreading techniques. In addition, the surface area finish gotten can usually decrease the need for comprehensive machining, additional improving its efficiency for high-precision parts utilized in various sectors, consisting of aerospace and automobile.

Quality Assurance in Light Weight Aluminum Spreading Production

Quality control in light weight aluminum spreading manufacturing is vital to ensure that products meet market criteria and client expectations. This entails different inspection techniques and approaches to examine the stability and high quality of the castings. Furthermore, compliance with well-known guidelines is critical to preserving item security and efficiency.

Evaluation Techniques and Techniques

Efficient inspection techniques and techniques are necessary for guaranteeing the stability and performance of aluminum spreadings. Different strategies are utilized to assure and spot problems quality throughout the manufacturing procedure. Aesthetic examinations are generally carried out to determine surface abnormalities, while non-destructive screening techniques, such as ultrasonic and radiographic inspections, evaluate interior frameworks without endangering the material. Furthermore, dimensional assessments utilizing coordinate measuring makers (CMM) confirm that castings fulfill defined tolerances. Chemical make-up analysis assurances that alloy specs are met, adding to the general high quality. Additionally, carrying out systematic tasting and statistical process control aids keep an eye on production uniformity. By making use of these varied examination strategies, producers can promote high requirements, ultimately bring about dependable and durable light weight aluminum castings for various applications.

Specifications and Conformity Laws

While sticking to strict criteria and compliance guidelines is crucial in light weight aluminum spreading manufacturing, it also ensures that products satisfy industry specifications and consumer expectations. Conformity with requirements such as ASTM, ISO, and SAE assures that aluminum castings have the called for mechanical homes, dimensional precision, and surface coating. Manufacturers have to execute quality assurance systems that include routine audits, screening, and documents to validate compliance. Furthermore, accreditations such as ISO 9001 show a commitment to high quality administration practices. By following these laws, producers can alleviate dangers connected to flaws and improve product integrity. Inevitably, adherence to established requirements cultivates trust fund and complete satisfaction among clients, placing business favorably within open markets while advertising continual enhancement in producing procedures.

Choosing the Right Aluminum Casting Solution

Exactly how can one guarantee they anonymous pick the most ideal light weight aluminum spreading service for their job? To begin, it is vital to evaluate the company's experience and know-how in the certain sort of light weight aluminum casting needed. Reviewing their profile can disclose their capability to take care of comparable projects properly. Additionally, evaluating client endorsements and seeking referrals can supply understandings into their dependability and quality of job.

Next, one need to consider the range of services provided, including design assistance, prototyping, and ending up choices. An extensive service carrier can simplify the manufacturing process and assurance uniformity in high quality. Moreover, it is important to verify compliance with market criteria and regulations, making certain the solution fulfills required requirements.

Getting quotes and comparing pricing frameworks permits for notified choices while thinking about value over expense. By complying with these standards, one can confidently select an aluminum spreading solution that satisfies project requirements and expectations.

Future Trends in Aluminum Casting Modern Technology

As the aluminum casting market evolves, arising technologies are readied to improve manufacturing processes and boost performance. Developments in additive production, particularly 3D printing, are allowing rapid prototyping and minimized lead times. This development enables for more complicated layouts that were formerly unattainable with typical approaches. Additionally, the combination of synthetic intelligence and artificial intelligence is improving quality assurance, forecasting flaws, and maximizing manufacturing routines.

Sustainability remains a critical pattern, with an increasing focus on reusing light weight aluminum and reducing waste during casting. Firms are buying energy-efficient heaters and procedures to decrease their carbon impacts. Wise spreading strategies that integrate IoT sensors are improving surveillance capabilities, giving real-time information to improve functional efficiency.

These fads suggest a change towards more cutting-edge, sustainable, and efficient practices in the aluminum casting field, guaranteeing that it remains competitive in a quickly altering manufacturing landscape.

Often Asked Concerns

What Is the Common Preparation for Light Weight Aluminum Spreading Projects?

The common lead time for light weight aluminum casting projects ranges from 4 to eight weeks, depending upon aspects such as layout complexity, production quantity, and the manufacturer's capabilities, guaranteeing high quality and prompt delivery to clients.

Exactly how Do I Figure Out the Right Alloy for My Task?

To identify the appropriate alloy for a task, one need to evaluate mechanical residential or commercial properties, rust resistance, thermal conductivity, and desired application. Consulting with professionals and referencing material specs can direct the choice procedure successfully.

Can Light Weight Aluminum Castings Be Recycled After Usage?

Yes, light weight aluminum castings can be recycled after usage. The recycling procedure is efficient, saving energy and resources. This lasting practice helps minimize environmental effect while advertising a round economy within the metal sector.

What Are the Cost Variables for Aluminum Spreading Providers?

Exist Environmental Regulations Related to Light Weight Aluminum Casting?

Yes, there are ecological guidelines related to light weight aluminum spreading. These regulations aim to use this link reduce exhausts, take care of waste, and assurance sustainable practices, requiring producers to stick to stringent guidelines to shield land, air, and water high quality.

Sand casting is understood for its versatility and cost-effectiveness, while die spreading gives excellent dimensional precision and surface coating. Sand casting stands out as one of the most prominent techniques for aluminum spreading due to its adaptability and cost-effectiveness. Financial investment spreading is renowned for its accuracy and ability to generate complex styles with limited tolerances, making it a very regarded method in the light weight aluminum spreading landscape. Financial investment casting is particularly useful for thin-walled parts and complicated shapes, which are testing to attain with various other casting techniques. As the aluminum spreading market progresses, arising technologies are established to reshape production procedures and boost performance.